-

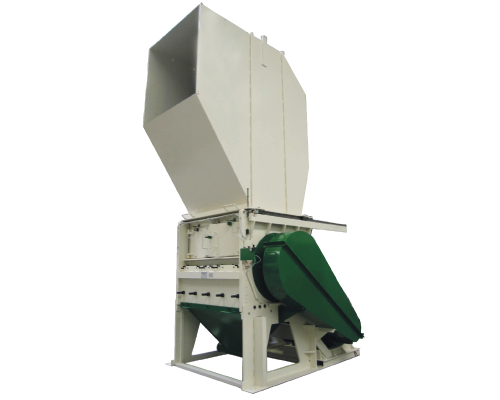

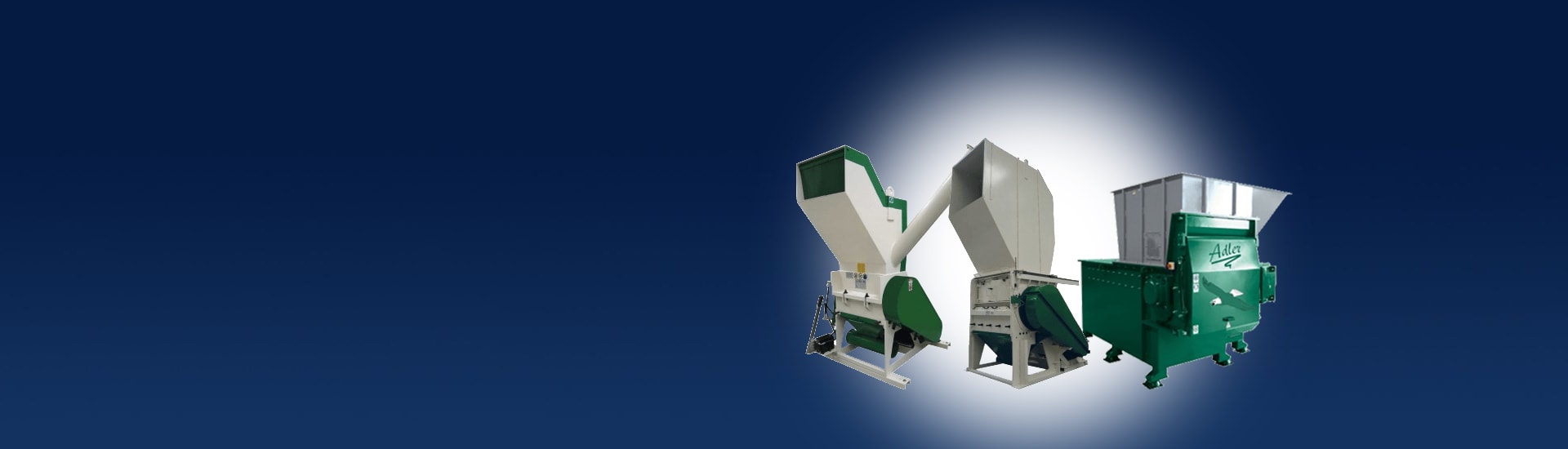

The Plastic

The Plastic

Processing

Equipment Specialists -

The Plastic

The Plastic

Processing

Equipment Specialists -

The Plastic

The Plastic

Processing

Equipment Specialists -

The Plastic

The Plastic

Processing

Equipment Specialists -

The Plastic

The Plastic

Processing

Equipment Specialists -

The Plastic

The Plastic

Processing

Equipment Specialists -

The Plastic

The Plastic

Processing

Equipment Specialists

Latest News

Introducing a Brand New Line for 2017: Funnels and Chutes designed to deposit mouldings onto a conveyor or into a […]