DESS

Overview

Drying Energy Saving System – DESS:

The highly developed and advanced DESS drying system from Main Tech will significantly reduce your energy consumption, improve the consistency and quality of your product. Therefore providing you a saving and giving you the competitive edge within your market.

The highly developed and advanced DESS drying system from Main Tech will significantly reduce your energy consumption, improve the consistency and quality of your product. Therefore providing you a saving and giving you the competitive edge within your market.

STANDARD FEATURES

- Fully insulated drying hopper equipped with capacitive rod level probe for continuous monitoring over 40 – 100% of the drying hoppers capacity. This level monitoring system also controls the material level in the hopper in-line with the material through-put and type of material being processed.

- Electrical or gas process air heating chambers are available from 1 – 150kw. The heating output is also proportionally controlled to ensure the benefit of the lowest energy watts/kg of material per hour.

- Heat recovery systems can be provided to save power in the process and regeneration air circuits, preventing wasting energy into the ambient surroundings.

- Cyclonic dust separators ensure collection of the smallest dust particles to extend the lifetime of the filter elements within the drying system. All filters are monitored by pressure differential switches to indicate when preventative maintenance is required.

- Dryers are fitted with inverter controlled process air blowers which are linked to the hopper capacity probes to ensure the correct air flow for the material being dried.

- Heat recovery monitor and diverter valves are used to control when there is sufficient temperature and heat energy (that would normally be exhausted away) to efficiently heat exchange into the process of regeneration air circuits.

- Dew-point control system ensures you have the correct dew point for the material type being processed. DP control provides you with a process guarantee as well as reducing the energy consumption in the regeneration circuit. The number of regeneration cycles and the time period between the are managed by the DP control system.

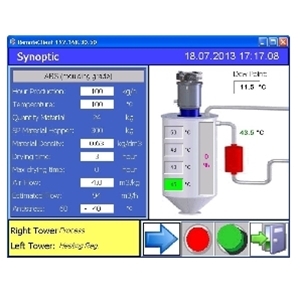

- Touch-Sys EVO control system provides the operator with high definition colour screen and graphic display of all the drying system functions.